15 September, 2023

15 September, 2023Fagor Automation will be at Hannover, at Hall 9 Stand J42 from September 18 to 23, showcasing all their latest novelties, among which robust and long-lasting encoders with patented 3STATECH technology, and next-generation CNCs featuring the innovative HMIelite interface from the company.

Since its establishment over forty years ago, Fagor Automation has kept its innovative spirit with a strong commitment to research and technological development, offering solutions tailored to customer needs and a range of cutting-edge products. Starting from initial models for milling and turning, the company also develops specific solutions for sectors such as semiconductors, aerospace, IT, medicine, large scientific facilities, metrology, and additive manufacturing, among others.

Advanced solutions to enhance productivity

Visitors to Fagor Automation's booth at EMO will have the opportunity to firsthand experience the company's latest innovations.

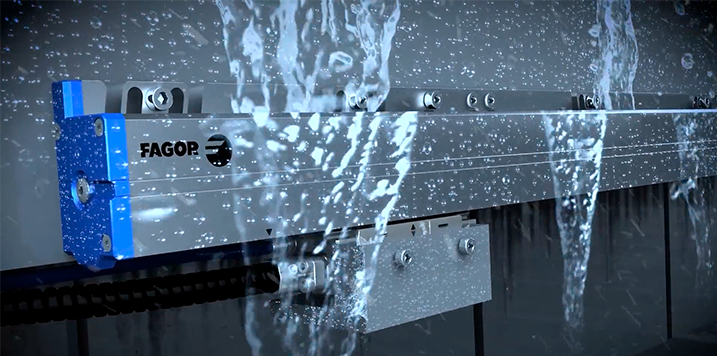

The S3, SV3, G3, L3, and H3 encoders are Fagor Automation's most advanced linear and angular encoders, forming the Series3, and among their features is the Functional Safety certification. Visitors will also get to know the new addition to the encoder catalog, the Series UT: a family of optical rings that complete the range of encoders for measuring any rotary application. These rings provide high rotation speeds and precision with the best resolutions, such as rotary tables and heads. All thanks to the exclusive 3STATECH technology patented by Fagor Automation.

Regarding CNC Systems, Fagor Automation will present its major innovation at EMO: HMIelite, the new multi-platform CNC interface based on HTML5 technology, offering numerous advantages to users. It is adaptable to all screen formats and designed to fully exploit the ease of use of touchscreen devices. Furthermore, it allows connectivity with remote and portable devices and offers multiple customization options. It adapts to the most demanding requirements of the current and future market. Additionally, the company will showcase the Quercus CNC system with more powerful control algorithms, a 100 MB communication bus, and a full digital system.

Digitization of processes: Fagor Digital Suite

Providing comprehensive automation solutions has always been a priority for Fagor Automation. In addition to offering a range of forefront products, they also offer solutions for the digitalization of production lines and other services tailored to the needs of their customers, including technical support and training.

Fagor Digital Suite is the innovative digitalization solution that Fagor Automation has launched in the market to meet the high demand from customers for process digitalization. Includes different modules for multi-brand and multi-protocol data capture, monitoring of indicators, production planning, administration and teleservice.This multi-brand solution, designed for users and manufacturers, enables the connection of machines with the rest of the production and management systems, capturing all necessary data and transforming them into valuable information to facilitate decision-making. It is compatible with the leading CNCs in the market and can be integrated with other systems.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.