04 December, 2020

04 December, 2020The ERLO GROUP, which specialises in the manufacture of machine-tools and components, has designed a strategic plan with its sights set on 2025 that will underscore its growth. The orders from CIE Automotive and Batz will also reinforce the Group's visibility in the design and manufacture of special high-technology machines (IBERMACH).

The Managing Director of the ERLO GROUP, Unai Zubeldia, believes that sales in 2020 will be very satisfactory and similar to those of the previous year. Given the consequences of the pandemic, this achievement is the result of "entering the confinement stage with a record portfolio of orders and not having had any cancellations during these months". However, he also admits that the recovery of the market in recent months has not stabilised their activity completely: "some investment decisions have been postponed", although he trusts that the increased activity of the automotive industry and the solid forecast for the energy sector will contribute to overcoming "the long-term challenges set forth in the Strategic Plan 2020-2025".

As explained by Mr. Zubeldia, the three pillars for advancement will rest on the commitment to growth, efficiency and service provisioning, which will foreseeably increase sales by more than 50% up to 2025, to over 12 million euros.

To reach these targets, the Group has designed a series of actions that rely heavily on intensifying both its commercial capacity and marketing. The plan to include sales staff and heads of international zones will be bolstered by the preparation of a network of partners, which will expand its offer of ERLO and IBERDRILL machining and drilling units and special IBERMACH machines beyond Western Europe. This includes alliances with the Midstates company in the United States (Ohio), the Turkish company Miri Machine (Esmirna) and the British company TayBourne, as well as an upcoming agreement with a Polish company.

The sales department will also be reinforced before the end of the year with an online store for the sale of drills and spare parts. Meanwhile, IBERMACH is working on "proactive sales of solutions with audiovisual means and success stories".

The progress made in efficiency adds to measures taken in management, organisation and investments. The goal is to reduce the delivery times of standard drills from three weeks to four days in the first quarter of 2021. To this end, a new lay-out has already been designed with the assistance of LKS and further work is being carried out on a modular design of their machines. Another area of improvement has focused on purchases management, for which a plan to recruit suppliers beyond the local setting has been drawn up.

Higher industrial production will be propelled by the purchase of a Zeiss 3D 500x500x500 mm measuring machine that will increase quality assurance capacity, and the upcoming inclusion of a DANOBAT grinding machine for the manufacture of various drill components. In the mid-term, the Groups is studying the purchase of a machining centre to provide service to their machinery divisions.

Provision of services will be channelled through ERLO SERVICES, which has obtained a dozen long-term preventive maintenance contracts for both on-site and remote servicing. In this case, the goal is to double their percentage of revenue by 2025, by which time they expect to contribute 15 percent of sales.

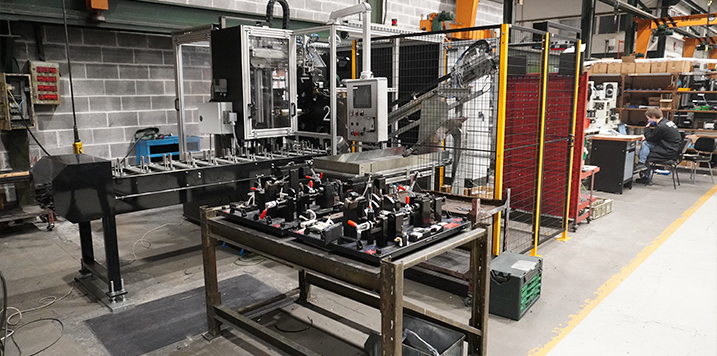

Another key factor for gaining ground on the market will be sharing high-technology turnkey projects, such as the current ongoing project for CIE Automotive and Batz, which will serve as a showcase for additional references. The manufacture of axle components for CIE will entail the delivery of three transfers to their subsidiaries Amaya Tellería and Mecauto. These cells, two of which have seven stations and a third with six stations, will carry out boring, drilling, reaming and threading operations.

As regards Batz, the project is being carried out for Lantegi Batuak, which will receive a special drilling cell for Nissan pedals with automatic powering and release, which has already spiked the interest of other multinational automobile companies.

Source: Empresa XXI.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.