11 March, 2024

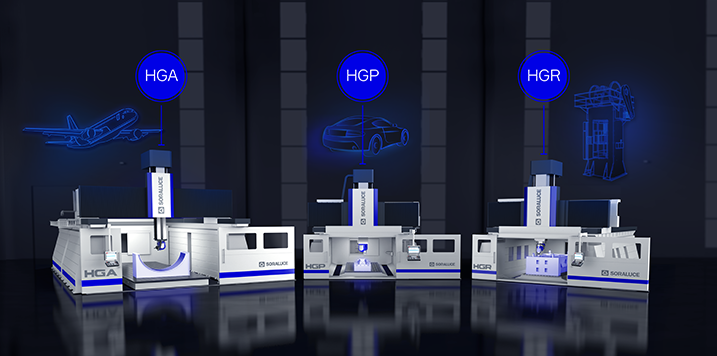

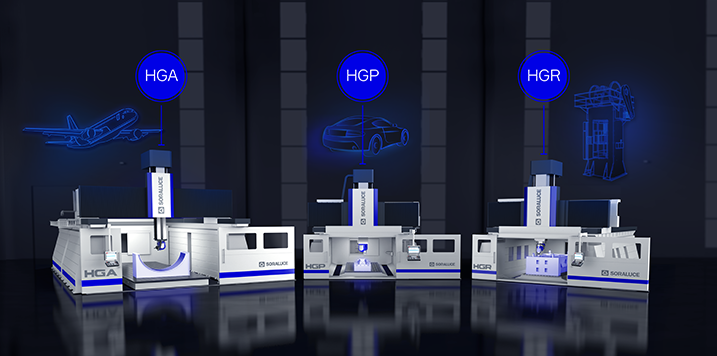

11 March, 2024Soraluce, a pioneer in milling, boring, multifunction and automation solutions, announces the launch of its revolutionary Dynamic Line, which includes the new high beam gantry machines. This new line epitomises precision, dynamics and efficiency, poised to revolutionise manufacturing processes in a variety of industries.

Soraluce's high-beam gantry milling machines are designed to drive manufacturing operations to unprecedented levels of performance. Offering high-speed cutting capabilities, exceptional accuracy rates and high-volume machining capacity, these machines are backed by Soraluce's extensive experience in the milling industry and proven leading-edge technology.

The Dynamic Line includes three machine models adapted to applications in sectors such as aerospace, moulds and dies and mechanical engineering, with solutions designed for specific materials such as composites, light alloys and steel components.

Tailored to the specific needs of various industries and applications, these machines can be equipped with 5-axis gyroscopic or high-torque milling heads. This versatility ensures perfect handling of sophisticated and complex shapes. In addition, they feature a comprehensive splash guarding system to maintain cleanliness and safety standards in the working environment. Furthermore, the incorporation of various dust extraction systems, both in the enclosure and integrated into the heads, facilitates the removal of dust and dirt generated during machining processes, thus maintaining optimum cleanliness during all operations.

High DynamicsUnprecedented efficiency with the Dynamic Line's high dynamic function with high-speed cutting capabilities. With spindle speeds of up to 60,000 mm/min and accelerations of up to 4 m/s², these machines are designed to push the limits of productivity.

Innovative 5-axis contouring heads with speeds up to 30,000 rpm. It's not just about moving fast; it's about moving with precision and finesse. Sophisticated designs and complex geometries can be achieved with these heads. Whether you are modelling an aerospace component or executing complex machining of moulds and dies, semi-finishes and finishes in steel or aluminium, the high dynamics function ensures that your machining operations are executed with unrivalled accuracy and efficiency.

Precision ExcellenceDynamic Line offers the best surface quality for your most demanding jobs. In precision engineering, every detail matters, and achieving flawless surface finishes is paramount. With Dynamic Line, excellence is not just a goal, but a guarantee.

One of the cornerstones of this commitment is thermal stability, which ensures that performance remains constant even despite temperature fluctuations and rigorous machining tasks. This stability is more than just a feature; it is a testament to the meticulous engineering that underpins every aspect of the Dynamic Line.

In addition, the Dynamic Line has highly calibrated kinematics, further enhancing its ability to deliver exceptional results. Every movement is precisely controlled, every movement meticulously calculated, ensuring that each component is crafted with the utmost precision and finesse.

But the excellence doesn't stop there. The high revolutions of the Dynamic Line enable long-lasting machining without compromising quality or performance. Whether you're engaged in marathon machining sessions or tackling complex designs that require extended run times, the Dynamic Line delivers consistent results time after time.

High Cutting CapacityAt the heart of the cutting capacity are our high-powered mechanical heads, designed to deliver unrivalled power of up to 73 kW. This extraordinary power ensures optimum performance, allowing users to tackle even the most demanding cutting tasks with ease and precision.

In addition, our solution offers a wide range of high-torque 5-axis mechanical contouring heads, with torque levels up to 2000 Nm. This versatility allows users to execute complex cuts with unprecedented precision, meeting a wide range of application needs in various industries.

To increase stability and performance, the new range integrates intelligent damping solutions such as DAS+ and DWS, complemented by a robust all-cast iron structure. These innovative features work together to minimise vibration and ensure consistent operation, even in the most demanding working environments.

"We are delighted to introduce the Soraluce high crossbeam gantry milling machines, which represent a new milestone in precision engineering," said Oier Elguezabal, Business Development Director at Soraluce. "These machines embody our commitment to innovation and excellence, enabling manufacturers to achieve unrivalled levels of productivity and quality in their operations.

11 March, 2024Soraluce, a pioneer in milling, boring, multifunction and automation solutions, announces the launch of its revolutionary Dynamic Line, which includes the new high beam gantry machines. This new line epitomises precision, dynamics and efficiency, poised to revolutionise manufacturing processes in a variety of industries.

11 March, 2024Soraluce, a pioneer in milling, boring, multifunction and automation solutions, announces the launch of its revolutionary Dynamic Line, which includes the new high beam gantry machines. This new line epitomises precision, dynamics and efficiency, poised to revolutionise manufacturing processes in a variety of industries.