07 June, 2022

07 June, 2022Developing innovative and pioneering solutions in the engineering field to promote the technological progress of machine-tool sector businesses, establishing new standards and responding to the most demanding machining challenges with high levels of productivity and efficiency. This is the concept that machine-tool manufacturer Soraluce has been perfecting over six decades, since its beginnings in 1962, and which has brought it to its current position of global leadership in milling, boring, multi-function and automation solutions.

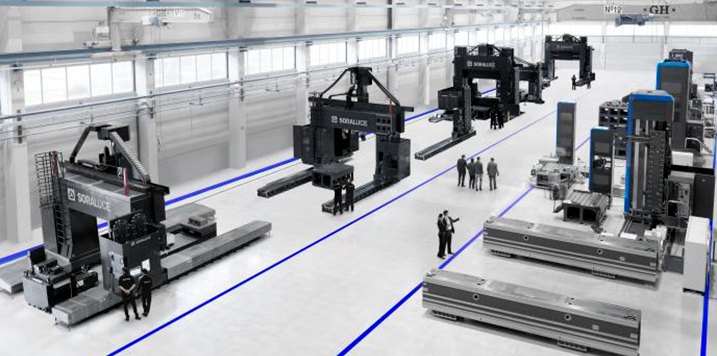

To commemorate its 60 years of activity, always at the forefront of technology, the firm organised a new edition of Soraluce Summit, which was held from 18 to 20 May at its facilities in Bergara. Over three days, the machine-tool manufacturer exhibited its customised, customer-focused offerings, which encompass three areas: latest generation machinery -Leader range-, state-of-the-art technological solutions -Smart technology-, and state-of-the-art digital services, the benefits of which were showcased through demos and live machining sessions.

Leader range

Higher production rates, greater precision, enhanced efficiency, increased output, more reliable use, improved ergonomics, safety and increased profitability, shorter cycle times, stoppages, consumption and emissions. Under this premise, Soraluce has been offering innovative solutions to the machine-tool sector for 60 years.

Among other new features, over these open days, the Basque company presented a new large-scale multi-function machine which integrates milling and turning processes, as well as a high level of automation, for the Austrian company Krones, world leader in production lines for the food and drinks industry.

The machine, which features a sliding table bridge architecture, incorporates two 6000 mm wide milling-turning rototranslating tables, 7100 mm rotations, with capacity for parts of up to 40 Tn. It has a selection of different milling and turning workheads and a 500-tool robotic tool magazine.

Smart technology

By means of a guided tour, Soraluce showcased the latest advances and projects in milling, boring, multi-function and automation, as well as new smart buffering solutions to increase the swarf removal capacity during machining. Attendees at the event had the opportunity to learn first-hand about all these technologies by watching live demos.

In this regard, at Soraluce Summit, the firm presented its active buffering system, DAS®, a smart system which oversees the machining process and selects the best technological alternative for eliminating vibrations, and its active buffering device, DWS (Dynamic Workpiece Stabiliser) for eliminating chatter or vibration in the machining processes of flexible parts, which earned it the 2020 prize for Quality Innovation of the Year.

Advanced digital services

In addition to the new features in machinery and technological solutions, the Gipuzkoa-based company also displayed its innovations in the field of industrial digitalisation, developed in full at the Soraluce Software Factory, its in-house centre for the development of advanced software solutions, technological advancements and digital services.

In this regard, Soraluce presented some of the advanced digital services with which it contributes to accelerating the digital transformation of the sector's companies, such as Autocheck for self-diagnosis of machine status; FactoryConnect for plant digitalisation; the EMaintain tool, which automates and digitalises maintenance processes, as well as the new functionalities of the Smart HMI smart interface, which enhances the efficiency of manufacturing processes.

To complete the new digital services section, the machine-tool manufacturer presented to the public for the first time its comprehensive monitoring platform “My Soraluce”, which enables enhanced control of current machine status. A new system which, according to Alejandro Martínez, director of Services and Solutions at Soraluce, “offers the client direct access to all information regarding the machine, enabling them to control its current status at all times and from any location, easily, quickly and clearly”.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.