06 September, 2019

06 September, 2019At EMO 2019, Schaeffler will be presenting innovative components for main spindles, feed axes, rotary axes, and rotary tables that will ensure more productivity, availability, and quality for machine tools. Schaeffler will present bearing series like the M-series FAG High-Speed spindle angular contact ball bearings, linear recirculating and guideway assemblies for linear axes equipped with DuraSense, and the YRTC rotary table bearings series. Latest software-based services for monitoring components, machinery, and processes will also be presented.

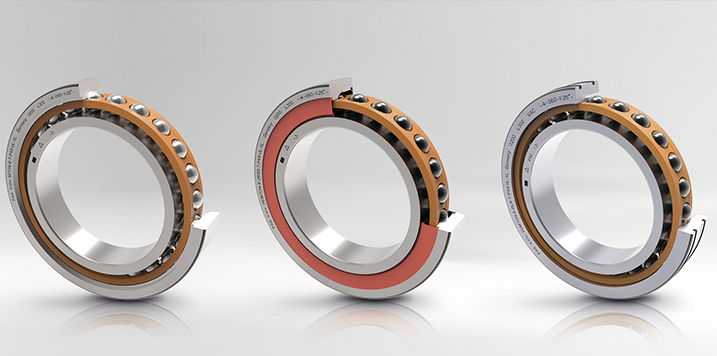

Available in three different versions, M, HCM and VCM, the M-series High-Speed spindle bearings in X-life combine the high-speed capacity of bearings with small balls with the robustness and load carrying capacity of large-ball bearings. M-series spindle bearings are manufactured entirely from 100Cr6, whereas HCM-series bearings are equipped with ceramic balls and the VCM High-Speed series also feature balls made from ceramic material, but with bearing rings made from the newly-developed Vacrodur high-performance material. Schaeffler will also present SpindelSense, innovative monitoring system for spindle bearings.

Schaeffler DuraSense is designed for the safe operation of INA linear recirculating ball or roller bearing and guideway assemblies. This sensor system monitors the tribological conditions of linear guidance systems based on vibration signals.

The three YRT and torque motor series for rotary tables will also be present at EMO. With these series, torque motor, rotary table, and angular measuring system can be perfectly matched to each other to get the required performance.

Schaeffler will also be presenting software solutions autinity VibroControl and FactoryHub for the first time. Together with Condition Analyzer, these three software-based services allow intelligent monitoring and the condition assessment of components and units from machines and production systems through to manufacturing processes.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.