24 June, 2022

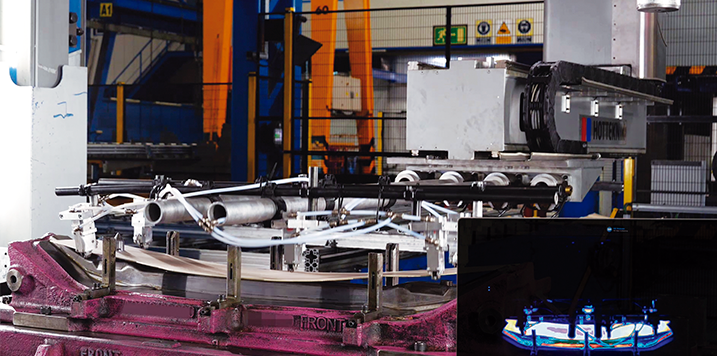

24 June, 2022Impression Technologies Limited (ITL) and Fagor Arrasate combine their knowledge to offer a complete high-volume technological and production solution for hot-formed aluminum structures. ITL, based in Coventry, UK, is the originator and world leader in hot forming aluminum through its proprietary HFQ® Technology process, which is the culmination of 20 years of developing know-how spanning characterization advanced alloy analysis, simulation models, tribology, and process settings unique to each part and alloy. Fagor is a global provider of customized solutions for sheet metal stamping that serves a wide range of market sectors, including the automotive sector.

HFQ technology has been used by premium brands such as Aston Martin and Lotus since 2016, and is being engineered into several new electric vehicle platforms globally, including body-in-white and electrical system housings. Interest in the application of HFQ for lightweighting vehicles, especially electric vehicles, is growing rapidly, creating a demand for new high-volume hot-press (HFQ) aluminum lines in major production regions of automobiles from Europe, China and North America.

The non-exclusive collaboration offers Tiers and OEMs a unique combination of materials, design, process optimization and manufacturing line capacity for high volume production of 6x and 7x series aluminum HFQ components. ITL will lead activities related to HFQ component design, simulation (including alloy selection and characterization, if required) and process specification; and Fagor will be responsible for the design and delivery of a highly competitive production facility accredited by HFQ. Tiers in the automotive sector (or OEMs who wish to have their own HFQ capability) are free to work with each company independently or request a complete and accredited HFQ production solution led by Fagor, with access to HFQ technology and ongoing technical support from ITL. Given the critical interdependence between design simulation and process parameters to achieve the required mechanical and dimensional specifications, the technical integration provided by ITL and Fagor will provide the stamper with an optimized capacity solution and reduced engineering burden.

Jonathan Watkins, General Manager of Impression Technologies, commented: "I am delighted to announce this new collaboration with Fagor Arrasate, one of the world's leading press line manufacturers, whose skills and capabilities complement those of ITL. We have had a record number of inquiries and our combined full-service offering will facilitate the adoption of HFQ technology and the creation of a strong global supply network."

Unai López, General Manager of Fagor Arrasate, added: "Tackling new technological challenges is part of FAGOR's DNA. The FAGOR - ITL collaboration is aimed at all those companies that are willing to take a step forward in material stamping technology. This new agreement, which we are excited to announce, introduces a game-changing collaboration in this field, with a technology partner like ITL, to help the industry meet the requirements of lightweight material stamping."

24 June, 2022Impression Technologies Limited (ITL) and Fagor Arrasate combine their knowledge to offer a complete high-volume technological and production solution for hot-formed aluminum structures. ITL, based in Coventry, UK, is the originator and world leader in hot forming aluminum through its proprietary HFQ® Technology process, which is the culmination of 20 years of developing know-how spanning characterization advanced alloy analysis, simulation models, tribology, and process settings unique to each part and alloy. Fagor is a global provider of customized solutions for sheet metal stamping that serves a wide range of market sectors, including the automotive sector.

24 June, 2022Impression Technologies Limited (ITL) and Fagor Arrasate combine their knowledge to offer a complete high-volume technological and production solution for hot-formed aluminum structures. ITL, based in Coventry, UK, is the originator and world leader in hot forming aluminum through its proprietary HFQ® Technology process, which is the culmination of 20 years of developing know-how spanning characterization advanced alloy analysis, simulation models, tribology, and process settings unique to each part and alloy. Fagor is a global provider of customized solutions for sheet metal stamping that serves a wide range of market sectors, including the automotive sector.