29 July, 2014

29 July, 2014The development of the electromechanical cushion is particularly interesting for servo presses.

In the second half of the 1990s, Fagor Arrasate developed the programmable hydraulic cushion. Hydraulic cushions stamp the part upwards, and this is an important advantage because it avoids the need to turn the part over between the first and second press. The slide pushes both the blank and the blankholder plate underneath the die downwards, pulling the blank towards the lower die. When the slide ascends, the cushion pushes the blankholder plate upwards, also raising the stamped part. Another advantage of this system is that the force of each cushion cylinder can be varied so it is better adapted to the part requirements. It also improves the repetitiveness of the drawing process.

This was an important development, clearly shown by the fact that other press manufacturers decided to use the very same concept developed by Fagor to produce their own hydraulic cushions. It is also demonstrated by the fact that today, double action presses are hardly used. The main inconvenience of this system is that it consumes a vast amount of energy during the stamping process. The pressure required to drive the cushion is created by throttling the oil with a servo valve, converting the stamping energy into heat. Not only does this waste the stamping energy generated by the press, but it also necessary to cool the oil that is heated during the process.

The main advantage of this system is that the energy needed for holding the part is returned to the network by the servo motor

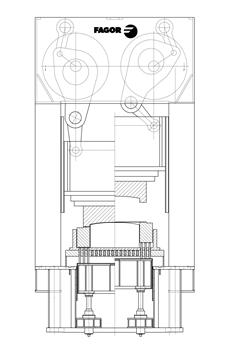

In recent years, the energy consumption of machines has been under increasing analysis due to environmental awareness, the culture of ecology and the need to reduce costs. Fagor Arrasate is firmly committed to creating technology that will improve the efficiency of the hydraulic cushion. To do this, it is already developing a new concept of electromechanical cushion. The cushion will be activated by a rack-pinion system that converts the lineal movement of the cushion into a rotating movement, connecting this rotating movement to an electric motor that controls the position and pressing force necessary to create the part. Fagor Arrasate is well aware of the rack-pinion system because, on a smaller scale, it uses it in various other processes, such as in destackers and blank feeding equipment. This development improves the mechanical properties of standard hydraulic cushions because the force, speed and pre-acceleration of the cushion are maintained while its capacity in the ascent phase is considerably increased.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.