28 September, 2021

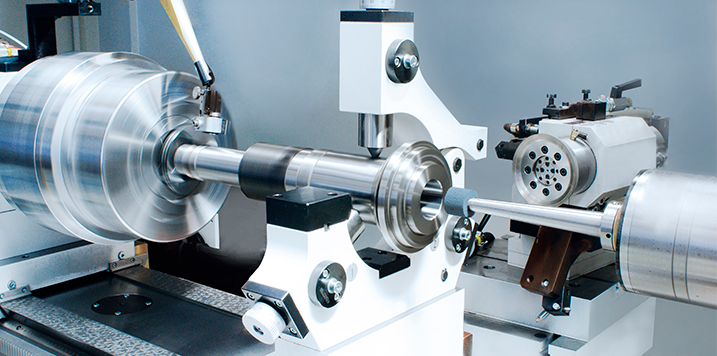

28 September, 2021Danobat-Overbeck, the German subsidiary, presents the ILD high-precision internal, external & radius grinding machine. A flexible solution capable of grinding highly complex parts which require different grinding processes in one set-up. During EMO, the ILD machine will be showing a demo part manufactured especially for this fair with no less than 30 eccentric holes.

In addition to this machine being suitable for grinding of deeper and longer ID´s, it allows for clamping of parts of up to 1300 mm with a swing of 760 mm in diameter. The configuration options of the B0 axis (+20º/-10º or +90º/-15º) makes it an effective solution for the production of precision parts requiring complex operations. It can grind tapered surfaces and allows automated cylindrical corrections. It is also possible to grind radii using interpolation. This in turn allows complex geometries to be machined in the part using coordinate grinding. It is even possible to make square, rectangular or free shapes with the highest level of precision.

Hembrug Machine Tools will present the new generation Mikroturn® finish hard turning machine with integrated gantry loader. The new generation Mikroturn® is a further development of the existing Mikroturn® 100 and features a complete new and modern design. It also incorporates many improvements in the field of thermal stability, machine stiffness and accuracies that have been implemented in the Mikroturn® 100 in recent years. In addition, by applying the latest generation of pumps and motors, noise levels have been reduced by more than 70%.

Hembrug started with Danobat working on the new design after the acquisition by Danobat in 2019. The modern and functional design is now in line with the Danobat style. The machine can also easily be equipped with Danobat´s in-house developed gantry loader. This ensures even greater productivity and efficiency with lower per-part costs, even in a high-mix and low-volume environment for which the new generation Mikroturn® will mainly be used. The new design, where the hydraulic unit and gantry loader are integrated into the machine body, has a smaller footprint than the current Mikroturn® 100.

Under the hood the new generation Mikroturn® still offers the highest finish hard turning precision levels on the market just as the Mikroturn® 100. Form and dimensional accuracies of less than 2 micron and surface roughness Ra of 0.1 to 0.4 micron in workpieces with hardness of up to 70 HRC are indicative for the precision level of the new generation Mikroturn®. Thanks to the wear free, hydrostatic bearing system this machining accuracy is maintained even after decades of use. The Hembrug Mikroturn® machines are used worldwide already for many years by renowned companies in the bearing industry, tool and mould making and machine construction. The new generation Mikroturn® is the next logical step in order to meet an ever increasing demand for productivity, accuracy and lower cost per workpiece.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.