14 de Septiembre de 2017

14 de Septiembre de 2017JUARISTI DEUTSCHLAND GmbH has been established in Germany coinciding with the EMO International Exhibition at Hannover (Germany). The new company comprises a showroom and its own official Technical Service in Düsseldorf area, with highly qualified local staff and was set up to have a more direct presence in the German Market and to serve customers more effectively.

INNOVATIVE SOLUTIONS IN HIGH PERFORMANCE BORING AND MILLING MACHINES

JUARISTI will be present at the EMO 2017 exhibition to show the latest technological developments available as well as new features in its already extensive range of boring, milling and machining centers.

In addition to the Planer type / Floor type Boring machines, Bed type / Moving column Milling machines, Universal / 5 axes Machining Centers, following innovations are available in different models:

- AFC: Adaptive control for optimization of machining processes.

- AHC: Automatic Head Calibration system

- SUPERVISOR: Software for integral production management

- OSASUN: Self-diagnosis software and Predictive maintenance.

- MULTIPROCESS Machining Centers (Milling-Turning) with turning tables Ø 1000 - 4000 mm.

- TILTING rotary tables: up to 100 ton, for offshore wind power sector.

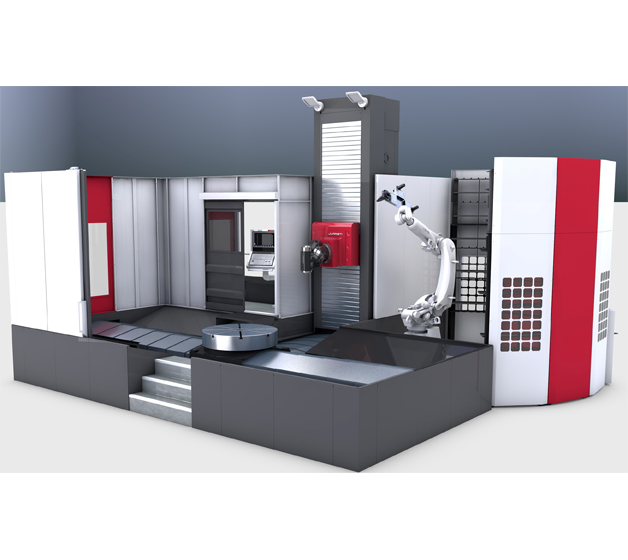

The TH3S model shown at the EMO is a High Performance Horizontal Boring-Milling Center with central head, combining optimum precision with a great machining capacity and a high automation level, with the use of Automatic Heads, Automatic head Changers, probes, etc.

With its remarkable dynamics, up to 40 m/min, it allows the use of state-of-the-art cutting tools with great chip removal rate capacity thanks to their high feed rates.

It’s a very flexible and cost-effective machine with outstanding features ideal for different application sectors such as energy, molds & dies, aerospace, transportation, subcontracting, etc

Suscríbete a nuestro boletín.