24 January, 2019

24 January, 2019As part of its R&D&i strategy, Lantek, a multinational pioneer in the digital transformation of the industrial metalworking sector, is strengthening its collaboration with its technological partner Vicomtech to advance the interactive 3D simulation of heat affected zones during sheet metal cutting processes.

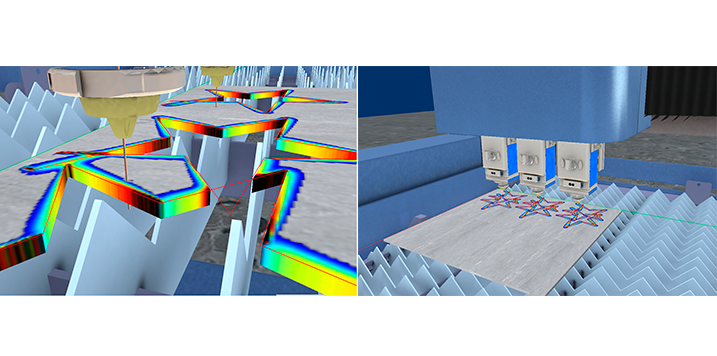

This collaboration builds on the results received from the BeroSim project, an initiative that gives users a 3D model that lets them see how heat affects sheet metal as it is cut and predicts the effects that it will have on the material (deformation, changes to thickness or quality, etc.) caused by high temperatures used in laser and plasma cutting processes. As a result of this project, this innovation was made available to the industry to increase production efficiency, generating significant savings on resources, by anticipating and avoiding potential material deformation during the cutting process.

With this renewed commitment, both organizations have taken one step further in their aim of offering the fabrication and sheet metalworking industry innovative solutions and services that respond to its needs and which provide real and continuous added value. Thanks to the research progress made by the Vicomtech Technology Center, algorithms have been developed to support multi-head cutting machines, improving their performance and the quality of parts.

The results of this solution have been verified and compared with those obtained from the existing software, and they were very satisfactory. A high speed of execution was achieved thanks to the use of modern graphics hardware (GPU) and the functional integration into an interactive simulation environment. The results of this technological advancement were endorsed by the journal Materials, a high-impact scientific publication, which echoed this research with an article entitled: “Fast Analytic Simulation for Multi-Laser Heating of Sheet Metal in GPU”

Benefits of these latest technology advances include:

The simulation of heat affected zones makes it possible to optimize sheet metal CNC programs before they get to the machine, making significant savings in material and in both human and machine resources.

With these simulation tools, companies can adapt to a changing and increasingly competitive global environment that is led by advanced manufacturing and where intelligent production is key to making the factory of the future a reality.

The simulation of sheet metal cutting processes is a phase of the production process that enables the definition of the best sheet metal strategy and cutting order while substantially improving output, making it possible to anticipate and detect possible unforeseen anomalies during the nesting and cut path phases. With these advanced technologies, the program does not need to be tested on the actual machine, resulting in savings in machine time, materials, and energy, while at the same time lessening the risk of potential incidents, breakdowns, and workplace accidents.

This technology has been proven using laboratory processes to calculate the heat distribution in materials and Lantek is currently analyzing its incorporation into commercial products for sheet metal manufacture. Asier Ortiz, Lantek’s Director of Operations, says "These virtual heat generation and dissipation models greatly help prevent the production of parts that will not pass quality assurance due to deformation or deterioration of their physical qualities as a result of excessive heat. In manufacturing processes, where fairly thick special materials are being worked with, anticipation of heat related problems is essential in order to ensure good results."

Dr. Jorge Posada, Associate Director of Vicomtech, gave a very positive evaluation of this collaboration, which fits perfectly with the center’s technology transfer mission. "Collaborating with Lantek is a great example in which a top company from the Basque region, though one with a clearly international calling, knew how to identify interesting problems and challenges requiring research and innovation that may have a global impact. For Vicomtech it is very satisfying to be able to contribute our scientific and technological expertise in this way and demonstrate that this collaboration has significant results at the international level."

The inclusion of cutting-edge technology in its processes and products allows Lantek to maintain its position as one of the global leaders in innovation within a very competitive and mature market. Additionally, the technological cooperation between Lantek and Vicomtech consolidates the relationship between both entities and complements their efforts in terms of innovation in the industrial sector.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.