16 June, 2017

16 June, 2017MAHERHOLDING GROUP and ONA ELECTROEROSION presented the result of their business collaboration for the first time at ADDIT3D (pavilion 5, stand C-50). ADDILAN is the result of the commitment to innovation and diversification of two major references in the Machine Tool sector that commit to Industry 4.0. ADDILAN is a newly created company engaged in the design, manufacture and marketing of additive machines with a high input rate.

Additive manufacturing (AM) is a technology classified as Industry 4.0, which permits manufacturing parts layer by layer, based on 3D data of a model, in contrast to subtractive manufacturing techniques. These technologies permit manufacturing 100% functional parts with a high added value. At the same time they are emerging technologies that complement the traditional machining and forming processes. Their main value proposal is to save raw material consumption, save energy and to reduce the time between design and end product.

Additive manufacturing is an Industry 4.0 technology that is changing the industrial manufacturing sector. According to data published in the last Wohlers’ Report (reference publication in the additive manufacturing sector) the business volume grew by 17.4% in 2016, reaching a total turnover of close to 6.06 billion dollars. The prediction is for additive manufacturing business to reach 16.24 billion dollars by 2020.

In this context ADDILAN was created, a company that was presented at ADDIT3D (pavilion 5 stand C-50), and whose activity focuses on the design, manufacture and marketing of high input rate additive machines, with WAAM (Wire Arc Additive Manufacturing) technology.

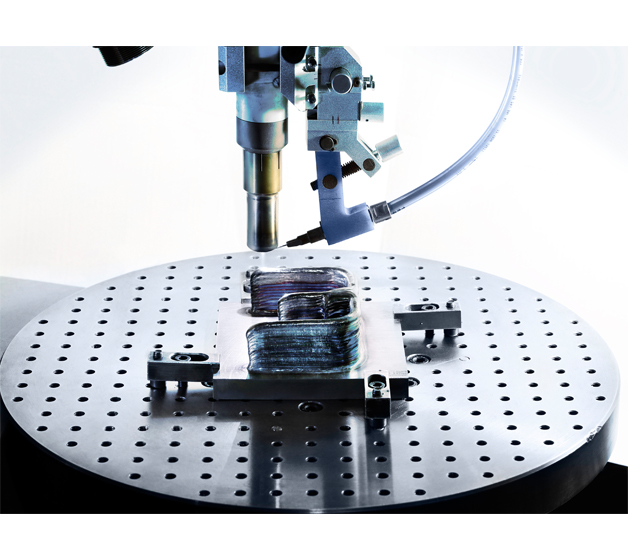

WAAM technology permits the manufacture of parts/preforms by means of arc welding and wire input technologies. ADDILAN’s main target market is the market of high value components, medium-large sized components in demanding industrial sectors such as the aeronautical, aerospace, energy or naval sectors. WAAM technology permits working with all materials used in welding, including steel, titanium alloys, superalloys and aluminium alloys. The machines have closed loop control and an inert chamber with a special loading and unloading system. All of this guarantees the quality of the part during the manufacturing process.

With the incorporation of ADDILAN, its promoters, ONA ELECTROEROSION and MAHERHOLDING GROUP commit to additive manufacturing and to offer high added value component manufacturers another competitive solution. The innovative design of the machines, its important technological development and solid experience as international machine-tool manufacturers for promoters, set the foundations on which ADDILAN can build its entire future, to establish its niche in the additive manufacturing sector.

The WAAM technology value proposal, compared with other additive technologies, is also worth highlighting. These machines manage to achieve greater input rates and the possibility of manufacturing larger parts/performs. Electric arc + wire based processes (WAAM) combine lower costs and high input rates (up to 10 Kh/h) with selvedges of less than 2 mm.

ADDILAN is associated with Addimat (Spanish Association of Additive Manufacturing and 3D Technologies) and it participated as an exhibitor at the ADDIT3D fair that took place from 6 to 8 June at the BEC.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.