01 April, 2015

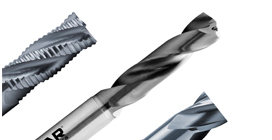

01 April, 2015The number one manufacturer of cutting tools revolutionises the hard metal market with a new and complete programme that covers the most common operations such as drilling, milling, etc.

It has just brought out its 2015 Industrial Catalogue, which it reserves for its most technical customers. As a result of the hard work carried out by the R&D&I team throughout 2014, IZAR has renewed and extended its programme, converting hard metal into the axis around which its manufacturing strategy evolves, as shown by the fact that this material opens every chapter of this catalogue.

We are talking about seven new milling references, plus a very important range extension in terms of existing references, as well as a very complete range for drilling, deburring, saws, rotary cutters, and, of course, a whole chapter for plates aimed at different operations.

At a more technical level, we can highlight the use of new hard metal qualities depending on whether the resulting tools are used for general use or work with aluminium (micrograins) or, on the contrary, a high performance intensive use or use on hard materials (ultra-fine grain) is chosen.

Noteworthy, too, is the fact that IZAR has updated the coatings that it uses to achieve a longer working life for its tools, selecting a new optimised coating for each type of operation. For example, a latest generation Alcro-Pro has been selected in front cutters, which in the case of rotary cutters, becomes Altin and in the case of a one-tooth cutter, a high-performance polycrystalline diamond for aluminium.

Within the innovative products that IZAR has launched onto the market, we can highlight new 2 and 4-tooth O-ring cutters, whose main characteristic is that they have a radius between 0.10 and 1.00 mm on the front edges, a special design to work on high hardness moulds. There are also three new references to work on aluminium at high cutting speeds, not forgetting an alternating 35-38º helix cutter, suitable for finishing work in the most demanding applications (up to 70 HRC).

Finally, the prices are adjusted downwards in existing references, both for general use and special references, converting IZAR into a top class European competitor, in its own right, in this type of high level tools.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.